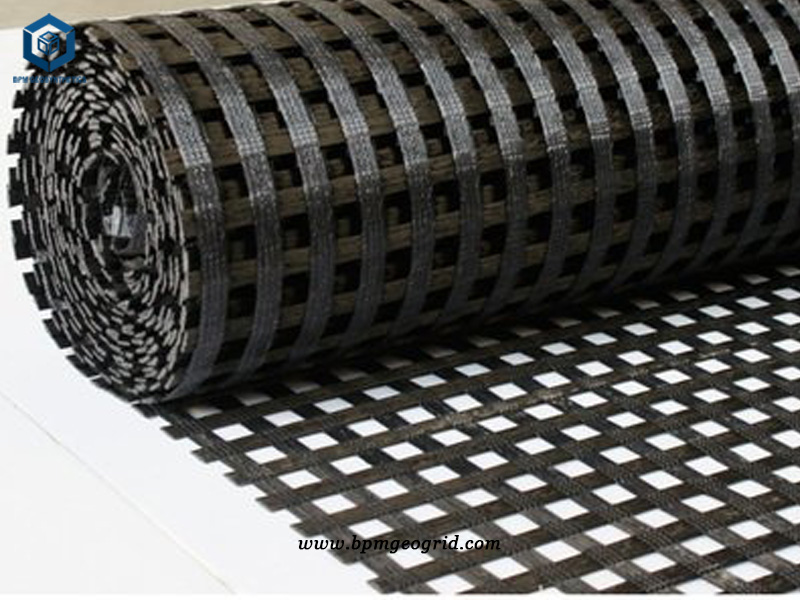

The raw material of warp knitted polyester geogrid fabric is polyester fiber. It adopts a warp knitting directional structure, the warp and weft yarns in the fabric are not bent with each other, and the intersections are bound and combined with high-strength fiber filaments to form a firm joint and give full play to its mechanical properties.

BPM company’s warp knitted polyester geogrid fabric has high tensile strength, small elongation force, large tear resistance strength, small difference in vertical and horizontal strength, anti-ultraviolet aging, wear resistance, corrosion resistance, light weight, and strong interlocking force with soil or gravel It has a significant effect on enhancing the shear resistance and reinforcement of the soil body and improving the integrity and load capacity of the soil body.

CASE STUDY

- Location :Thailand

- Product(s) : 120/30kN warp knitted polyester geogrid

- Application : highway

Issue

A customer in Thailand informed us that he got a government project to rehabilitate a highway, which required the use of 120/30kN warp knitted polyester gratings. After the customer sends us the product index, we confirmed it, and after verification, it was consistent with the product we are producing. According to the quantity requested by the customer, we calculated the packing quantity and sent the quotation to the customer. At the same time, we sent our inspection report. The project requires a total of 20,000 square meters, and we recommend that customers use 1*40HQ containers.

Since they are our old customers, they are very assured of our quality and price. After the project preparations are completed, the customer places an order. Half a month after placing the order, the customer received the goods, and after ten days of construction, the project was completed. After testing, the project has been completed very well, and customers are full of praise for our products, and their trust in us has increased.

Specifications warp knitted polyester geogrid fabric for highway in Thailand

- Total warp knitted polyester geogrid –20000 squares meters

- Specifications – 120/30kN

- Each roll size is – 4m x100m

Solution

Over the past few decades, geosynthetics, particularly geogrids, have been used to create a reinforced earth mass to support highway superstructures and resist lateral earth pressure, especially seismic action. Many geogrid-reinforced soil abutments are constructed overseas and they perform very well, especially during large geohazard events. In Thailand, these structures are not common. Geogrid reinforced soil abutment is a bridge abutment composed of interlayer granular soil and geogrid material.

In expressway construction, the first problem to be solved is soft soil foundation. Soft soil foundation is usually treated by a combination of sand cushion and plastic drainage board, but due to the large upper load, uneven settlement and slippage will be caused. Laying biaxial geogrid and filament non-woven geotextile at the bottom will increase the friction force, strengthen the roadbed and soft soil, greatly prevent uneven settlement and sliding, and play an important role in improving the overall stability of the roadbed.

The use of warp knitted polyester geogrid fabric

- The warp-knitted polyester geogrid is used to reinforce the soft soil subgrade of various roads, such as highways, railways, municipal roads, etc., which can effectively improve the strength of the subgrade and delay the reflection cracks of the road.

- Reinforcement and isolation of dams and rivers in water conservancy projects, strengthen soft soil foundations, enhance their protection capabilities, and improve the bearing capacity and stability of foundations.

- The warp-knitted polyester geogrid is used for embankment slope reinforcement, retaining wall reinforcement to enhance overall strength, and soft soil foundations such as roads, railways, and water conservancy.

- The warp-knitted polyester geogrid is used for the protection of railway slag: due to the vibration of the train and the wind and rain, the ballast is lost, and the geogrid is used to wrap the ballast to prevent the loss of the ballast and improve the stability of the roadbed;

Warp knitting Polyester Geogrid Features

*High tensile strength, high wear resistance

*Excellent mechanical properties and long-term stability

*Anti-corrosion resistance

*Balanced vertical and horizontal strength

*Adaptive to the most terrain shape, especially sloped or crooked surfaces

*Low weight – does not require special equipment to lay out

*Better ability to withstand the differential settlement

*High resistance to dynamic shock loading and seismic activity

*Excellent soil surface adaptability, especially the sloped or curved surface

*High resistance to dynamic impact load and vibration activity

*Excellent resistance to differential settlement

*Reinforcement and stabilization of riverside, embankment and side slope, retaining wall construction

*Easy to deployment, long service life

*High quality, factory price

Construction method of warp knitted polyester grid

The grating should be laid on the coarse-grained stone of the asphalt layer of the construction road. The original pavement should be leveled first. After finishing, trimming and cleaning, the construction should be carried out. For ordinary gratings, special steel nails should be used to fix the gratings. The joints are horizontal. The asphalt-treated geogrid is more than 5cm long and the length is greater than 10cm. Sprinkle as little bitumen sticky oil as possible. Use self-adhesive geogrid for construction. After moderate rolling by rubber wheel rollers, the asphalt mixture can be paved and pressed. Solid, no specific nails are required to fix it.

After the geogrid is paved, the upper layer filler is laid manually, and the rolling is completed in time to avoid long-term exposure to the sun. Then, the material is transported, leveled and rolled mechanically. The mechanical paving and rolling are pushed from both sides to the middle, and the rolling is carried out from both sides to the middle, and the compactness is maintained to meet the specification requirements. All construction vehicles and construction machinery shall not be driven or parked on the paved geogrid. The quality of geogrid shall be checked at any time during construction. If any damage is found, such as breakage, puncturing and tearing, it shall be repaired according to the degree or replace.

About BPM

BPM manufactures and supplies many types of effective and state of the art geogrid, geomembrane, geotextile, and geosynthetics to over 36 countries. Our main innovative, high quality geogrid products include plastic biaxial geogrid, fiberglass geogrid, plastic uniaxial geogrid, warp knitting polyester geogrid, and steel plastic georgic mesh, etc. BPM brand brand high quality geosynthetic products had been certificated by the ISO9001, ISO14001,OHSAS18001 Soncap, SASO and BV, SGS and Intertek, etc.

If you have any questions or inquiries, please fill in and submit the form to contact us.

About BPM

BPM manufactures and supplies many types of effective and state of the art geogrid, geomembrane, geotextile, and geosynthetics to over 36 countries. Our main innovative, high quality geogrid products include plastic biaxial geogrid, fiberglass geogrid, plastic uniaxial geogrid, warp knitting polyester geogrid, and steel plastic georgic mesh, etc. BPM brand brand high quality geosynthetic products had been certificated by the ISO9001, ISO14001,OHSAS18001 Soncap, SASO and BV, SGS and Intertek, etc.

If you have any questions or inquiries, please fill in and submit the form to contact us.