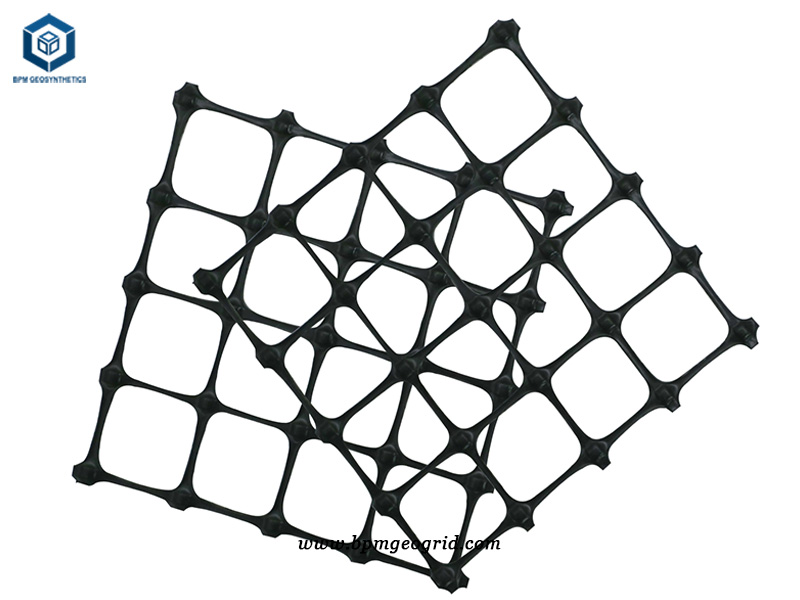

Biaxial HDPE geogrid is a major geosynthetic material with unique properties and efficacy compared with other geosynthetics. The biaxial HDPE geogrid is often used as a reinforcing material for reinforced soil structures or a reinforcing material for composite materials. The HDPE geogrid is divided into four categories: plastic geogrid, steel-plastic geogrid, glass fiber geogrid, and polyester warp-knitted polyester geogrid. The biaxial geogrid is a two-dimensional or three-dimensional mesh screen with a certain height, which is made of polypropylene, polyvinyl chloride and other polymers through thermoplastic or molded. When used in civil engineering, it is called a geotechnical HDPE geogrid.

Generally speaking, when dealing with bad foundations or rebuilding old roads, HDPE geogrid can increase the bearing capacity of the foundation, speed up the construction progress, control the development of settlement of soft foundation sections, shorten the construction period, and put the road into use as soon as possible. HDPE geogrid plays the role of strengthening the soil and improving the integrity, which is equivalent to the steel bars in concrete.

Case analysis

- Destination – New Zealand

- Products – Biaxial geogrid

- Usage – Urban road restoration works

Issue

The site along Cameron Town Road, south of Pukekohe, included a steep slope material constructed using unsuitable fill, which when combined with the build-up of hydrostatic pressure following a storm event resulted in sliding failures and the need for frequent repairs. Due to budget constraints, small retaining structures were constructed over a 3-year period to mitigate minor landslide and bank erosion issues. However, these failed and eventually resulted in a major landslide that reduced a 30m section of Cameron Town Road to a single lane.

Solution

The general contractor for the project provided the design for the project, a steep 20m high slope that needed to be reinforced with biaxial HDPE geogrid. After communicating with the contractor, our company recommended two-way plastic geogrid, and suggested piling 7-meter-deep wooden poles along the foot of the slope to improve the overall stability. And BPM assists in the construction phase. BPM two-way plastic geogrid was used as the main reinforcement material for the slope, which not only met the technical requirements of the engineer for this project, but also provided the contractor with the benefit of using wide rolls, saving cost through quick and easy installation and minimal waste .

Specifications of Biaxial HDPE Geogrid for Urban Road Restoration Project in Indonesia

- Product Name:Geogrid

- Total Quantity –28,440 Square meters

- Each roll Size – 3.95mx50m

Geogrid Mechanism

The mechanism of geogrid strengthening soil exists in the interaction between geogrid and soil. Generally, it can be summarized as the friction between the grid surface and the soil; the locking effect of the grid holes on the soil, and the passive resistance of the grid ribs. These three functions can restrain the lateral displacement of soil particles, thereby increasing the stability of the soil itself, and the reinforcement effect on the soil is higher than that of other geotextiles.

What aspects should be paid special attention to in the construction of geogrid engineering?

- When storing and laying the biaxial HDPE geogrid, avoid long-term exposure to the sun, otherwise it will easily deteriorate the performance indicators. The vertical laying of geogrids is omitted, and the specific location of the overlap must be carried out according to the construction drawing standards, and the connection must be firm. For the strength wall, the specific position of superimposed splicing should not be less than 20cm.

- The construction quality of the biaxial HDPE geogrid should meet the engineering construction standards stipulated in the design and construction drawings. During the whole process of engineering construction, no wrinkling, overlapping, twisting, etc. should occur, and the geogrid must be kept in a tight state. , so that the force is evenly distributed. If it is manually tightened, the geogrid should be close to the ground, the force should be uniform, and the surface flatness should be good. In addition, the geogrid needs to be fixed with pins to avoid displacement.

The successful application of biaxial HDPE geogrid is expected to reduce various common diseases of embankments in high-intensity earthquake areas, and improve the earthquake resistance and disaster reduction ability of roads. As a leading Geogrid Manufacturer, Supplier and Wholesaler, our quality complies with ASTM GRI-GM13 standards. In addition, we have obtained CE, ISO9001, ISO14001 and ISO45001 certificates. Our customer projects include geogrid retaining wall, road geogrid, environmental protection (landfill, sewage treatment), mining (heap leaching tank, tailings) and many other projects, and the customer satisfaction is 100%.

Features of Geogrid

- It has strong tensile strength, the tensile strength range is 25-110kn/m, and the tensile strength also varies according to the product model. 2. The stress elongation is small, and it has good ability to stabilize and strengthen the structure. 3. High physical and chemical stability, good anti-aging, anti-buried and anti-corrosion properties. 4. The coefficient of friction is significant, and the mesh structure is completely integrated into the earth and rock design to enhance structural stability. 5. Strong resistance to environmental stress, small deformation when the stress increases, and small temperature deformation coefficient in the range of -20 ° C to 120 ° C. The width is generally 4-6 meters, the weight is light, the installation and construction are simple, convenient, efficient and cheap.

When geogrid used?

- HDPE Geogrid use for roads and railways, which can reduce the settlement difference between the roadbed and abutment, reduce the vibration of vehicles and roadbeds, slow down the deformation of roadbed structures, and ensure safe and comfortable driving.

- Geogrid can be used for roadbed reinforcement, so that the granular filler and grid interlock together to form a stable plane, prevent the filler from sinking, and can disperse the vertical load. The area can be reinforced with multiple layers. The geographical conditions are harsh

- Geogrid use in parking lots or airport runways in commercial and industrial facilities

- The application of geogrid in embankment and subgrade filling can increase its stability and reduce the occupied area.

- Geogrid use for pavement reinforcement, so that mesh cloth and pavement materials are mixed together to disperse and transmit loads and prevent pavement cracks

About BPM

BPM manufactures and supplies many types of effective and state of the art geogrid, geomembrane, geotextile, and geosynthetics to over 36 countries. Our main innovative, high quality geogrid products include plastic biaxial geogrid, fiberglass geogrid, plastic uniaxial geogrid, warp knitting polyester geogrid, and steel plastic georgic mesh, etc. BPM brand high quality geosynthetic products had been certificated by the ISO9001, ISO14001,OHSAS18001, Soncap, SASO and BV, SGS and Intertek, etc.

If you have any questions or inquiries, please fill in and submit the form to contact us.