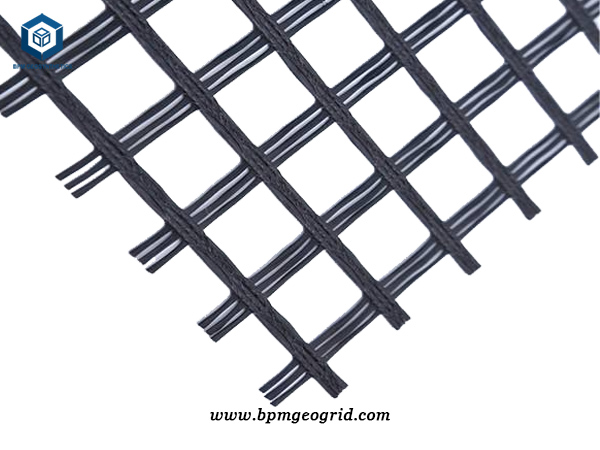

Fiberglass geogrid is the ideal geosynthetic material to reinforce the soft soil, cement, concrete, asphalt for the road surface or roadbed, etc. Fiberglass geogrid is made from excellent non-alkali fiberglass filament as the base material coated with adhesive by automatic woven technology. Fiberglass geogrid can can make full use of yarn textile strength and warp knitting directional structure to improve its high tensile strength, excellent tensile modulus, good wear resistance and creep resistance, and excellent thermal stability, etc. It can largely increase the bearing capacity of the ground and prolongs the service life of the road. Due to its high vertical and horizontal tensile strength, low unit extension and high flexibility, fiberglass geogrid is widely used to reinforce the embankment, asphalt pavement, road surface, prevent highway harm such as crack and rut from occurring, solve the problem that asphalt road surface is difficult to reinforce.

Fiberglass Geogrid Specifications

| Item |

GSB30-30 |

GSB40-40 |

GSB50-50 | GSB80-80 | GSB100-100 | GSB125-125 | GSB150-150 | |

|---|---|---|---|---|---|---|---|---|

| Size of mesh (mm) | 12.7*12.7~25.4*25.4 | |||||||

| Tensile Strength (kN/m) | Longitudinal | ≥30 | ≥40 | ≥50 | ≥80 | ≥100 | ≥125 | ≥150 |

| Transverse | ≥30 | ≥40 | ≥50 | ≥80 | ≥100 | ≥125 | ≥150 | |

| Elongation Rate (%) | ≤4 | |||||||

| Temperature Resistance (℃) | 100~280 | |||||||

Fiberglass Geogrid Features

- High tensile strength and tensile modulus

- Excellent wear resistance and creep resistance

- Low elongation

- Excellent temperature range

- Good anti-age and alkali-resistance

- Excellent thermal stability

- Nesting, interlock and restraint effects

- Overall improvement of road base

- Especially suitable for all types of asphalt mixes

- Extending service life

- Easy installation

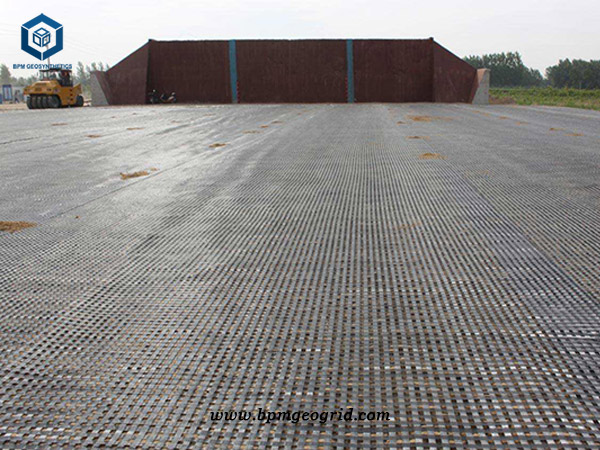

Fiberglass Geogrid Application

- Reinforcement of roads and crack prevention for airport runways, taxiways, roads, bridges, parking lots, jointed concrete highways to control reflective cracking.

- New highway construction, and other road maintenance or repair jobs to improve pavement life.

- Expanding thoroughfares and road lanes.

- Asphalt reinforcement at locations subject to intensive vehicle braking or accelerating, important junctions, bus stops etc.

About BPM

BPM has been manufacturing and supplying one stop geogrid products and solutions to worldwide customers since its foundation in 2007. BPM had provided many types of effective and state of the art geosynthetics such as geogrids, geomembranes, geotextiles, geocells, geosynthetic clay liners (GCLs), drainage boards to over 36 countries. Our customers are from Australia, France, Sweden, UK, Hong Kong, Hungary, New Zealand, Poland, Mexico, Ecuador, Brazil, Pakistan, Bangladesh, Thailand, Vietnam, Malaysia, Indonesia, Singapore, Philippines, Sri Lanka, India, UAE, Saudi Arabia, Qatar, Kenya, Ghana, Ethiopia, Somalia, Nigeria, South Africa, Swaziland, Mongolia etc.

BPM is not only manufacturing best quality geogrid products but also providing professional design and installation service. OEM, ODM and custom fabrication are also available. If you have any questions or inquiries, please fill and submit the following form, we will reply as soon as possible.